PMC offers consultation and training for achieving Operational Excellence through integrated management philosophies and methodologies. We enhance processes and provide services for developing, implementing, auditing, and maintaining Operational Excellence.

Request a Quote

PMC’s customized approach to operational excellence includes training and support for implementing improvements using lean methodologies.

Our team is experienced in industry-standard lean tools and methodologies including:

5S

Muda, mura, and muri

Six Sigma (DMAIC)

Design for Six Sigma (DFSS)

8D Methodology

Environmental Management

Environmental Management

Occupational Health and Safety Management

Our key services to improve operational excellence are time tested:

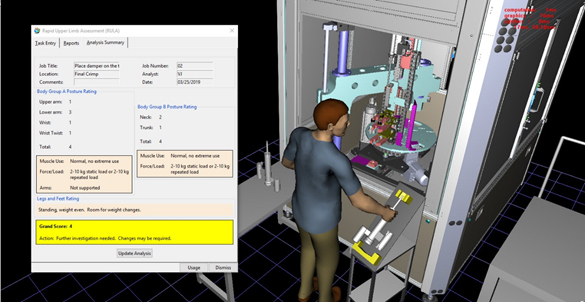

Ergonomic Assessment

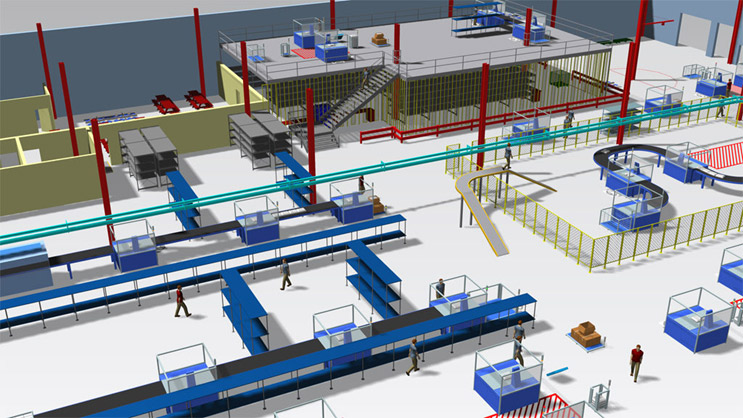

Lean Automation Manufacturing Consulting

Work Measurement Consulting

Value Added Analysis Services and Non Value Added Activity Analysis

Line Balancing Consulting Services

PMC brings over 40 years of expertise in Lean manufacturing consulting and operational excellence services, making us one of the leading operational excellence consulting firms. We serve diverse markets with proven tools and techniques. Our professionals offer a range of services, including:

Carefully choosing techniques tailored to address your specific challenges

Implementing the most suitable methods for your industry

Providing detailed optimization reports to improve your production processes

"Thanks to PMC, our workflow is now smoother than ever. They helped us streamline our processes and optimize our layout, which resulted in a 25% boost in efficiency and noticeable cost savings."

"We saw a big jump in productivity and slashed our operational costs within just a few months. PMC’s engineers made a real difference with their expertise in lean automation and quality."

"We’ve seen a 20% improvement in efficiency and a big drop in waste and cycle times. Their support has been fantastic. PMC made a huge difference by helping us introduce visual management tools and refine our processes. "

PMC provides diverse training courses in Industrial Engineering, covering Six Sigma, Lean Manufacturing Techniques, and 8S Core Courses. These programs are tailored to bolster your organization's manufacturing capabilities and promote operational excellence.

Send a message to our team by filling out the form below. Describe your project, ask questions, or even request a bid.

An expert from our team will be in touch with you within one business day!