Overview

Workplace ergonomics is the science of designing the workplace, keeping in mind the capabilities and limitations of the worker. A workplace ergonomics improvement process removes risk factors that lead to musculoskeletal injuries and allows for improved human performance and productivity.

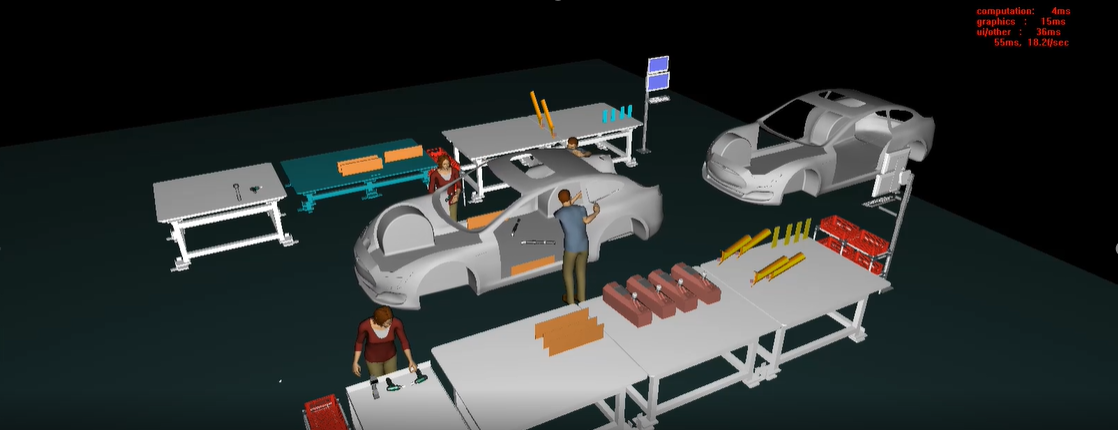

It’s best to integrate ergonomics into the planning, design and validation stages of your product lifecycle, and into the development of new equipment, workstations and processes from the start. Both Jack and Process Simulate Human software products enable you to size your human models to match worker populations and tests designs for multiple additional factors.

Case Studies

Continental Automotive Systems

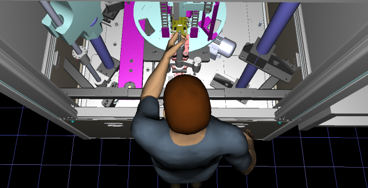

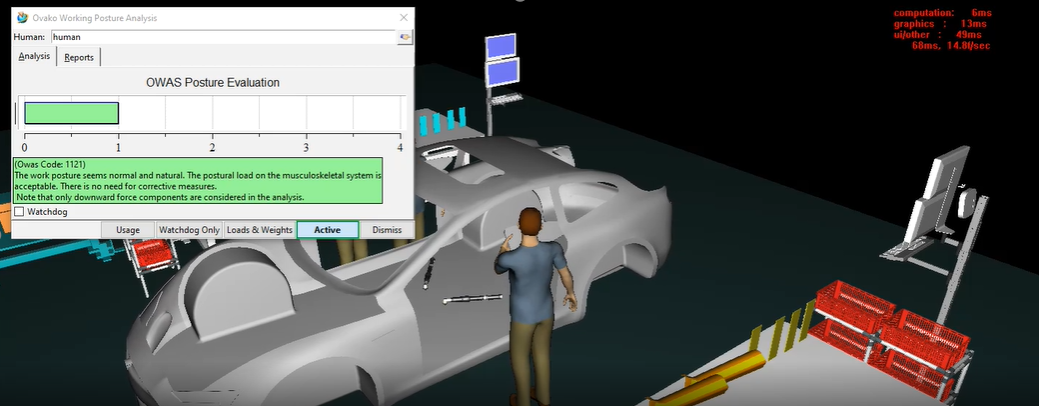

Ergonomics Simulation provides the user the ability to analyze virtual products or manual tasks within a virtual environment. Using software like Tecnomatix Jack and Process Simulate Human, injury risk, user comfort, reachability, energy expenditure, fatigue limits and other important human parameters are all measurable.

Ergonomic tools such as Tecnomatix Jack software create a virtual representation of the human to mimic postures, mechanical loads and performance of the human in a simulated environment to develop and improve the design of products and work spaces.

An effective ergonomics improvement process requires a continuous improvement framework. Doing so will improve labor productivity, lower employee turnover rates, and reduce cost related to absenteeism and injuries. A case study of a world class ergonomic program measured the following dramatic results.

- A 78% reduction in worker’s compensation costs

- A 15% increase in productivity

- Quality improvements

- Higher employee morale and better safety culture

Contact Us

Please write your questions in the following form and we will get to you as soon as possible. We look forward to helping you achieve your goals.