University of Michigan Steel Detailing

HISTORY

Operated by The Central Power Plant (CPP) team, the CCP generates and processes steam, electricity, compressed air, and domestic hot water for the University of Michigan Central and Medical Campuses. The CPP is a combined cycle cogeneration power plant that includes seven steam boilers totaling 1,000,000+ pounds of steaming capacity. In connection with the University of Michigan’s transition towards more eco-friendly alternatives, U of M has undertaken multiple construction projects to reduce the carbon footprint of the University.

THE CHALLENGE

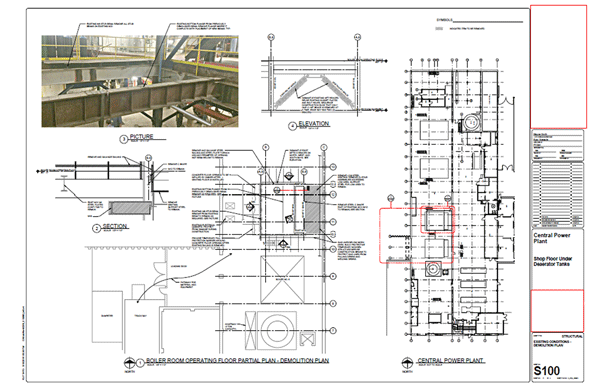

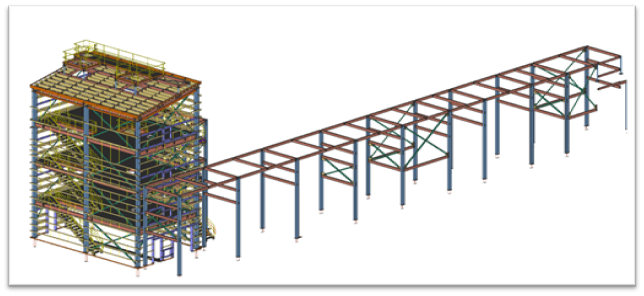

In the University of Michigan’s efforts to remove outdated infrastructure, a 3-story boiler was removed from one of the campuses buildings. This left a large hole in the structure that needed to be filled in to create walkable floors for storage and new energy options. To create these floors they needed to pour new concrete and erect steel beams, requiring steel detailing drawings. PMC was commissioned to provide these steel detailing drawings of the space to construction engineers. PMC facilitated the technical steel detailing drawings utilizing existing engineering drawings, point cloud data acquired by FARO Laser Scanners, SDS2, and reviewed with FARO WebShare.

Thanks to the measurements from the point cloud, PMC was able to identify several early-stage issues that provided cost and time savings for the project:

- Alterations for missed piping runs in the design documents

- Redesigning wall mounting to avoid poor demolition of previous concrete

- Adjusting floor framing to avoid grinding abandoned plates from mating beam flanges

A fifteen-minute scan performed by the FARO Laser Scanner helped the PMC team make construction suggestions that saved days on the project.

THE SOLUTION

Chris Mounts, using a FARO Laser Scanner, took three laser scans of the site in under fifteen minutes. The scans revealed a simpler solution to the problem. The point cloud images of the site allowed the team to see that they did not have to grind the plates off and the beam placements could simply be shifted. Instead of having to employ a millwright to grind the metal plates off the beams, the team was able to make recommendations for alternatives. By adjusting where the new beams were to be installed, they were able to avoid utilizing a millwright therefore avoiding additional expenses and saving time.

PMC was able to suggest slight measurement changes to construction plans addressing the removal of a staircase. An inconveniently placed L-bracket, bolted to the wall and a damaged piece of concrete would have normally required smashing the concrete, adding mortar to smooth it out, days of labor, etc. The point clouds showed that by altering the placement of the floor by 4 inches, they could avoid additional construction to the site.

- Steel Detailing of University of Michigan

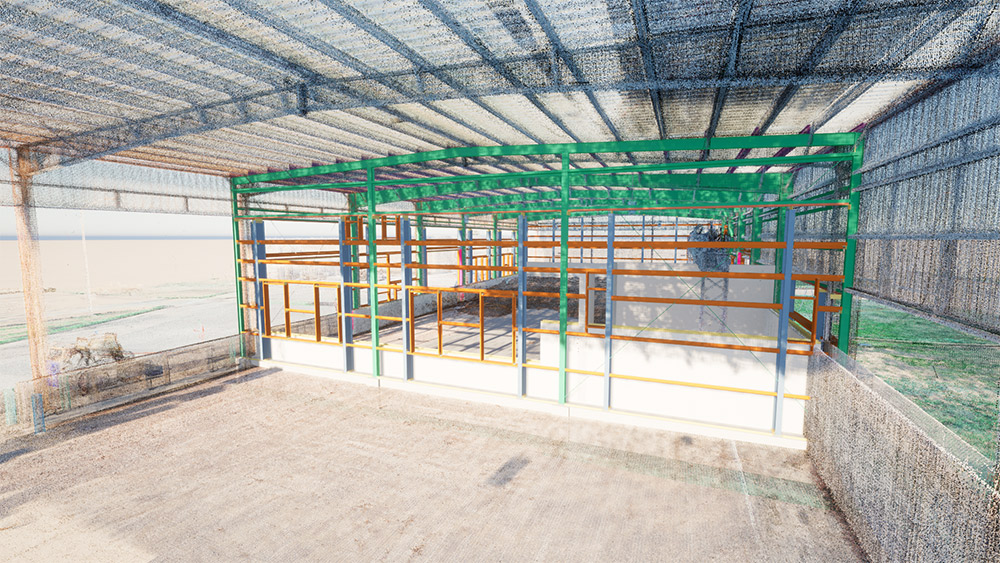

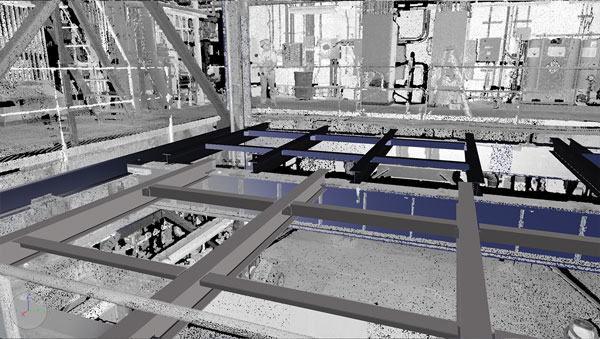

- Reality Capture Point Cloud over CAD Model

- Reality Capture Point Cloud over CAD Model

Contact Us

Please write your questions in the following form and we will get to you as soon as possible. We look forward to helping you achieve your goals.

Recent posts